Copyright 2026 The Garage | Disclaimer | Cookieverklaring | Privacyverklaring

2425 s2 - Biobased Wet Cell

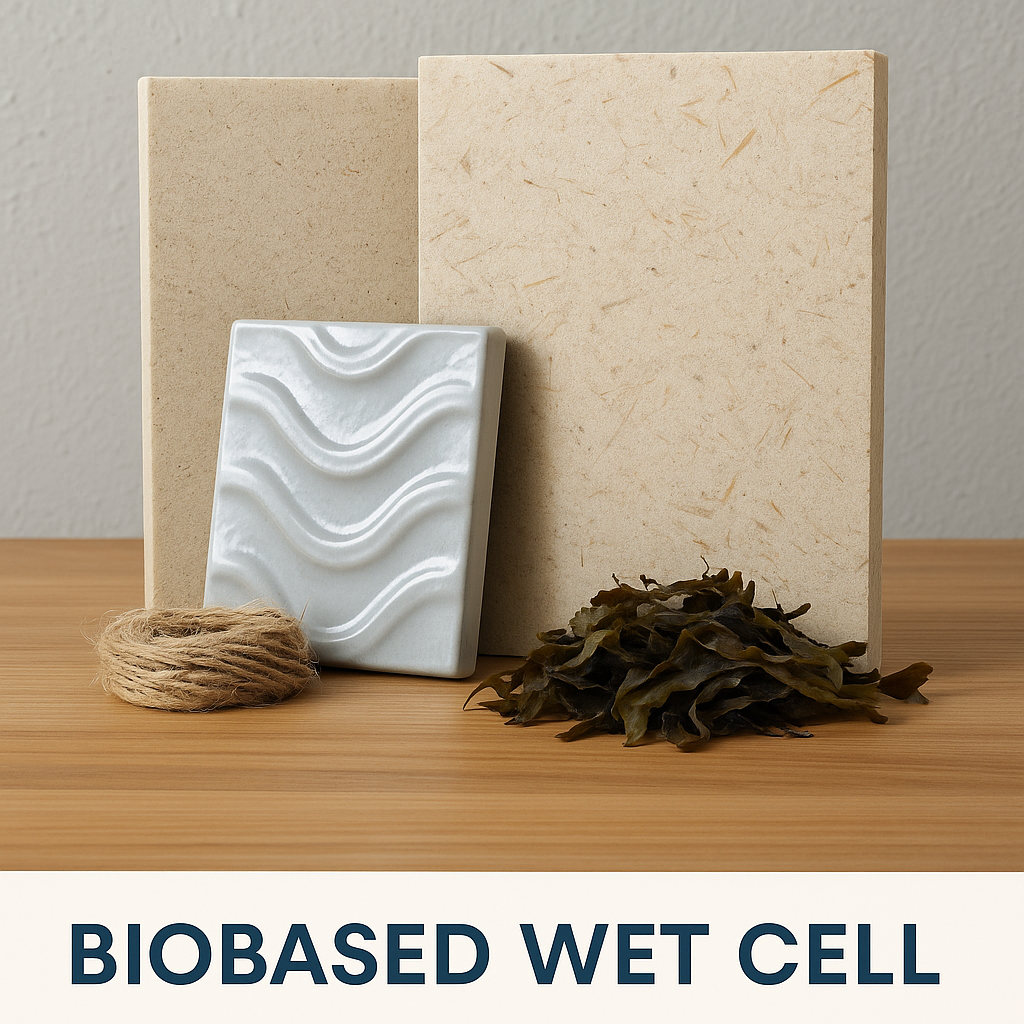

In the Biobased Wet Cell project, researchers are looking to use biobased materials to make water-resistant wall panels for wet rooms, such as a bathroom. Marianna Coelho from the Biobased Building lectorate at HZ University of Applied Sciences is leading the project, which runs until the end of 2025. Biobased Wet Cell develops water-resistant wall panels for humid spaces (e.g., bathrooms) using geopolymeric or alkali-activated materials combined with seaweed-derived alginate and natural fibers. By replacing some sand and gravel with pretreated fibers, the panels become lighter, stronger (flexural strength roughly doubles), and better insulated (thermal and acoustic), while still meeting durability requirements. Alginate acts as a binder, and its extraction is integrated with fiber pretreatment in a single alkaline process—streamlining production and cutting CO₂ emissions. After optimizing geopolymer mixes, prototypes are tested with students and industry partners; a full wet-cell installation will follow, preparing this biobased solution for real-world use. This RAAK SME–funded project fosters collaboration between knowledge institutions and companies to advance sustainable building materials.

Presentation

About this project

| Start date: | 02/03/2025 |

|---|---|

| Project description: | The construction industry is undergoing a critical transformation as it faces mounting pressure

to meet climate targets and material sustainability goals. One of the most urgent challenges lies in reducing the carbon emissions associated with conventional cement-based construction materials, which remain the dominant yet environmentally detrimental option in structural and non-structural applications. Although alkali-activated materials (AAMs) such as granulated blast furnace slag (GBFS)-based geopolymers have emerged as promising low-CO₂ alternatives, their widespread implementation is hindered by key durability and processing limitations—particularly in high-humidity or wet environments. This study seeks to move beyond empirical tweaking and instead focus on uncovering fundamental mechanisms that affect geopolymer stability and functionality in humid conditions. Ultimately, it aims to deliver a modified mixture and curing method capable of producing a geopolymer tile with low porosity, minimal efflorescence, consistent structural performance, and resilience in wet environments. the central research question is: How can the composition and curing conditions of a slag-based geopolymer be optimized to significantly improve water resistance and alkali stability, without compromising mechanical performance, in high-humidity environments? |

| Outcomes: | The cured material does not exhibit a highly polymerized geopolymeric alumino-silicate structure. XRF analysis revealed a lower-than-expected alumina content (~8% vs. 12%), resulting in a high Si/Al ratio (~4.67), which limits stable geopolymer formation. This leads to weaker silica-rich gels prone to alkali leaching.

Efflorescence (sodium carbonate) indicates strong alkali migration, while leachates consist mostly of amorphous silica. Unexpected mass gain after drying is likely due to CO₂ reacting with residual sodium silicates, forming stable gels, making gravimetric analysis unreliable. Recommendations: Adjust mix design by adding aluminosilicates (e.g., metakaolin or kaolinite) to reduce the Si/Al ratio to the optimal range (1.75–2.25). Investigate alternative, low-energy aluminosilicate sources like volcanic ash, pumice, or perlite. Use MAS NMR to better understand the structure and behavior of silicon and aluminum species in both the cured material and the silicate solutions. |

| Commissioned for: |

Marianna Ansiliero de Oliveira Coelho

(Lectoraat Biobased Bouwen)